1. Ifihan ati Ọja Loriview

This manual provides essential information for the safe and efficient installation, operation, and maintenance of your Pedrollo JSWM3CM single-phase 220V water pump. Please read this manual thoroughly before installation and use to ensure proper function and longevity of the product.

Figure 1: Pedrollo JSWM3CM Water Pump. This image shows the complete assembly of the Pedrollo JSWM3CM water pump, highlighting its compact design and robust construction.

The Pedrollo JSWM3CM is a self-priming surface pump designed for handling clean liquids with low sediment content. It is suitable for various applications including domestic water supply, agricultural irrigation, and light industrial use. Key features include a durable AISI 304 INOX impeller and a high-efficiency IE3 class electric motor.

2. Alaye Aabo

Awọn Itọsọna Aabo pataki: Nigbagbogbo tẹle awọn iṣọra aabo ipilẹ lati dinku eewu ina, mọnamọna, ati ipalara ti ara ẹni.

- Ensure the power supply matches the pump's specifications (220V single-phase).

- Nigbagbogbo ge asopọ agbara ṣaaju ṣiṣe eyikeyi itọju tabi fifi sori ẹrọ.

- Má ṣe lo fifa omi náà pẹ̀lú àwọn okùn tàbí àwọn púlọ́ọ̀gù tó ti bàjẹ́.

- Dáàbò bo fifa omi kuro ninu otutu otutu ti o tutu.

- Rii daju didasilẹ to dara lati ṣe idiwọ mọnamọna.

- Do not pump flammable or corrosive liquids. This pump is designed for clean water only.

- Pa awọn ọmọde ati awọn eniyan ti ko ni aṣẹ mọ kuro ni fifa ẹrọ ti n ṣiṣẹ.

3. Product Components and Design

The JSWM3CM pump is engineered for reliability and performance. Understanding its main components is crucial for proper installation and maintenance.

Figure 2: Internal Components of the Pedrollo JSWM3CM Pump. This diagram illustrates the key internal parts of the pump, including the pump body, impeller, motor, and shaft, providing insight into its robust construction.

Awọn eroja pataki:

- Ara fifa: Constructed from cast iron, capable of withstanding service pressures up to 10 bars.

- Olutayo: Made of AISI 304 INOX for durability and efficient water handling.

- Ejector Diffuser: Manufactured from NORYL.

- Atupa: Aluminum construction with an inox pump bottom.

- Mọto ina: 2900 rpm, IPX4 protection rating, Class F insulation, S1 continuous service. Features an IE3 class for high efficiency and low power consumption. Includes integrated thermal protection for safety.

- Coupling Shaft: Made of INOX EN 10088-3 - 1.4104.

4. Imọ ni pato

| Sipesifikesonu | Iye |

|---|---|

| Olupese | Pedrollo |

| Itọkasi awoṣe | JSWM3CM |

| Agbara | 1.10 kW |

| Oṣuwọn sisan | 0 si 7.2 m³/h |

| Head (HMT) | 20 to 54 mita |

| Ibi ti ina elekitiriki ti nwa | Nikan-alakoso 220V |

| Iyara mọto | 2900 rpm |

| Idaabobo Rating | IPX4 |

| Kilasi idabobo | F |

| Continuous Service Type | S1 |

| Fifa ara elo | Simẹnti Irin |

| Ohun elo Impeller | AISI 304 INOX |

| Iwọn | 31 kilo |

5. Fifi sori (Eto)

Proper installation is critical for the pump's performance and longevity. Follow these guidelines carefully.

Olusin 3: Example Installation Diagram. This illustration demonstrates a typical setup for the Pedrollo pump, showing the suction height (HS) and the placement of a non-return valve for optimal performance.

- Ibi: Install the pump in a dry, well-ventilated area, protected from direct sunlight, rain, and freezing temperatures. Ensure sufficient space for maintenance.

- Iṣagbesori: Securely mount the pump on a stable, level surface using appropriate bolts to minimize vibration.

- Laini afamora:

- The pump is self-priming and recommended for drawing water from depths of less than 9 meters.

- Use a rigid, airtight suction pipe with a diameter equal to or larger than the pump's suction port.

- Install a foot valve with a strainer at the end of the suction pipe to prevent debris entry and maintain prime.

- Ensure the suction line slopes upwards towards the pump to avoid air pockets.

- Laini Ìtújáde: Connect the discharge pipe to the pump's outlet. Install a gate valve on the discharge side to regulate flow and facilitate maintenance.

- Asopọmọra itanna:

- Connect the pump to a single-phase 220V power supply.

- Ensure the electrical circuit is protected by a suitable circuit breaker and residual current device (RCD).

- The motor has built-in thermal protection, but additional external protection is recommended for critical applications.

- All electrical connections must be performed by a qualified electrician in accordance with local regulations.

- Ipilẹṣẹ: Before first use, fill the pump casing completely with clean water through the priming port until it overflows. Replace the priming plug securely.

6. Isẹ

Nígbà tí a bá ti fi sori ẹrọ tí a sì ti ṣe àtúnṣe rẹ̀, fifa omi náà ti ṣetán fún iṣẹ́.

- Bibẹrẹ fifa soke:

- Ensure the pump is fully primed.

- Open the discharge valve partially or fully.

- Switch on the power supply to the pump. The pump should start immediately and begin pumping water.

- Abojuto: Ṣàkíyèsí pọ́ọ̀pù náà nígbà tí ó bá ń ṣiṣẹ́ fún àwọn ìró, ìgbọ̀n, tàbí jíjò tí kò wọ́pọ̀.

- Idaduro fifa soke:

- Pa àtọwọdá itusilẹ.

- Switch off the power supply to the pump.

- Ise Tesiwaju: The pump is designed for continuous S1 service, meaning it can operate continuously under a constant load.

7. Performance Abuda

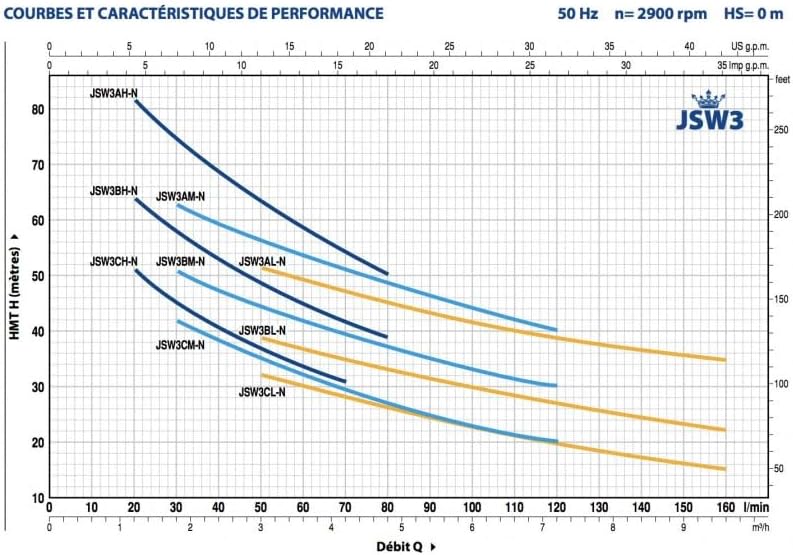

The performance of the Pedrollo JSWM3CM pump is characterized by its flow rate (Q) and total head (HMT). Refer to the performance curve diagram for detailed information.

Figure 4: Performance Curves for JSW3 Series Pumps. This graph illustrates the relationship between flow rate (Q) and total head (HMT) for various models within the JSW3 series, including the JSWM3CM, at 50 Hz and 2900 rpm.

The graph shows how the pump's head (pressure) decreases as the flow rate increases. Locate the curve corresponding to the JSWM3CM model to understand its specific operating range. The pump delivers a flow rate between 0 and 7.2 m³/h and a head between 20 and 54 meters, depending on the operating point.

8. Itọju

Regular maintenance ensures optimal performance and extends the pump's lifespan. Always disconnect power before maintenance.

- Awọn iṣayẹwo deede:

- Inspect the pump and piping for leaks.

- Check electrical connections for signs of wear or corrosion.

- Listen for unusual noises during operation.

- Ninu: Periodically clean the pump's exterior to prevent dust and debris buildup, which can affect cooling.

- Foot Valve/Strainer: Regularly inspect and clean the foot valve strainer to prevent blockages and ensure proper water intake.

- Igba otutu: If the pump is exposed to freezing temperatures, drain all water from the pump casing and piping to prevent damage from ice expansion.

- Igbẹhin ẹrọ: Èdìdì ẹ̀rọ náà jẹ́ apá kan tí ó máa ń bàjẹ́. Tí ìjò bá ń jò láti ibi tí ọ̀pá náà wà, ó lè nílò kí onímọ̀-ẹ̀rọ tó mọ̀ nípa rẹ̀ rọ́pò èdìdì náà.

9. Laasigbotitusita

Apá yìí fún ọ ní ìdáhùn sí àwọn ìṣòro tó wọ́pọ̀ tí o lè bá pàdé. Fún àwọn ìṣòro tí a kò kọ síbí, kan sí àwọn òṣìṣẹ́ iṣẹ́ tó péye.

| Isoro | Owun to le Fa | Ojutu |

|---|---|---|

| Pump ko bẹrẹ | No power supply; Thermal overload tripped; Motor fault. | Check power connection and circuit breaker; Allow motor to cool and reset; Consult a technician. |

| Pump runs but no water is delivered | Pump not primed; Air leak in suction line; Suction lift too high; Foot valve clogged. | Re-prime the pump; Check suction line for leaks and tighten connections; Reduce suction depth; Clean foot valve strainer. |

| Ṣíṣàn omi kekere tabi titẹ | Partial blockage in suction/discharge; Air in system; Worn impeller; Incorrect pipe sizing. | Check for blockages; Bleed air from system; Inspect impeller for damage; Verify pipe diameters. |

| Ariwo pupọ tabi gbigbọn | Cavitation (air in water); Unsecured mounting; Bearing wear; Debris in pump. | Ensure proper priming and no air leaks; Securely mount pump; Consult technician for bearing/debris. |

10. Atilẹyin ọja ati Support

Information regarding specific warranty terms and conditions for the Pedrollo JSWM3CM pump is typically provided at the point of purchase or within separate warranty documentation. Please refer to your purchase receipt or contact your supplier for details.

For technical support, spare parts, or professional servicing, please contact an authorized Pedrollo service center or your product retailer. Always provide the model number (JSWM3CM) and serial number (if applicable) when seeking support.