1. Ọja Ipariview

The Tekmar 303P Switching Relay is designed to manage up to three thermostats and operate circulators within a zoned hydronic heating system. This device facilitates efficient heat distribution by connecting to various zones and prioritizing heating demands as configured. Zone 1 offers an optional priority function, making it suitable for applications such as indirect domestic hot water tanks.

Key functionalities include optional pump exercising to prevent circulator seizure during periods of inactivity, and an optional post-purge operation for the last active zone to enhance energy efficiency. The 303P also provides a RoomResponse signal, which can optimize boiler efficiency and comfort when integrated with modulating-condensing boilers.

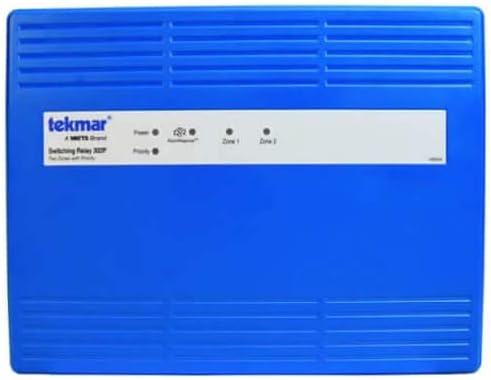

olusin 1: Iwaju view of the Tekmar 303P 3-Zone Priority Switching Relay. The blue enclosure features a white label indicating the brand "tekmar", model "Switching Relay 303P", and LED indicators for Power, RoomResponse, Priority, Zone 1, Zone 2, and Zone 3.

2. Awọn ẹya ara ẹrọ

The Tekmar 303P Switching Relay incorporates several features designed to optimize hydronic heating system performance and user convenience:

- Away Signal Sharing: Compatible with Tekmar thermostats for shared away signals.

- Awọn Ifọwọsi Aabo: CSA approved for reliable operation.

- Ibamu Thermostat: Works with all low voltage thermostats.

- Ilẹ: Equipped with four ground screws for secure installation.

- Idaabobo Circuit: Fuses protect both transformers and pumps from electrical overloads.

- Awọn Atọka Ipo LED indicators for each zone, priority status, end switch, and RoomResponse™ activity.

- Ifiweranṣẹ lẹhin: Optional feature to run the last operating zone's circulator for a short period after the call for heat ends, maximizing energy transfer.

- Priority Override: Allows Zone 1 to take precedence over other zones, typically for domestic hot water.

- Pump Exercising: Periodically activates circulators to prevent seizure during extended periods of inactivity.

- RoomResponse™ Signal: Provides a signal to modulating-condensing boilers to optimize comfort and improve boiler efficiency.

- Awọn Ipa ọna Ipa: Top, bottom, and back conduit knockouts for flexible wiring installation.

- Awọn Fuses apoju: Includes two spare fuses for convenience.

- Imugboroosi agbegbe: Supports unlimited zone expansion with additional relays.

- Zone Priority: Configurable priority for specific heating zones.

3. Imọ ni pato

| Sipesifikesonu | Iye |

|---|---|

| Ọja Iru | Adarí |

| Nọmba ti Awọn agbegbe | 3 |

| Ohun elo apade | Cover: ABS plastic, Base: galvanized steel |

| Apade Iru | NEMA type 1 |

| Awọn ifọwọsi | CSA C US |

| Awọn ipo Ibaramu | Lilo inu ile nikan, 32 si 122°F (0 si 50°C), RH 90% ti kii-condensing |

| Ibi ti ina elekitiriki ti nwa | 115 V (ac) ±10%, 60 Hz, 16 A |

| Amunawa | 40 VA, expandable to 80 VA with additional transformer M3069 (sold separately) |

| Awọn fiusi | T5A 250 V slow blow (two spare fuses included) |

| Pump Relays | 115 V (ac), 5 A, 1/3 hp, 16 A combined |

| Boiler End Switch (XX) | 24 V (ac), 5 A |

| DHW End Switch | 24 V (ac), 5 A |

| Modulating Boiler Output | 0-10 V (dc) 500 ohm min load impedance / 4-20 mA 1 k ohm max load impedance |

| Asopọmọra Iru | Dabaru |

| Iṣagbesori Iru | Oke Oke |

| Ipo Isẹ | Laifọwọyi |

| Wattage | 5.22 watt |

| Coist Resistance | 50 ohms |

| Coil Voltage | 115 Volts |

| Kere Yipada Voltage | 105 Volt (AC) |

| O pọju Yipada Voltage | 115 Volts |

| O pọju Yipada Lọwọlọwọ | 5 Amps |

| UPC | 384929979532 |

4. Fifi sori ẹrọ ati Oṣo

WARNING: Electrical installation should only be performed by qualified personnel. Ensure power is disconnected before beginning any wiring procedures to prevent electric shock.

4.1 Iṣagbesori

- Select a suitable indoor location for surface mounting, away from direct sunlight, heat sources, and excessive moisture.

- Ensure adequate space for wiring and ventilation.

- Secure the relay to a wall or suitable surface using appropriate fasteners through the mounting holes.

4.2 Awọn isopọ onirin

The Tekmar 303P features screw terminals for all electrical connections. Refer to the wiring diagram provided with the product packaging for detailed connection points. General connections include:

- Ibi ti ina elekitiriki ti nwa: Connect the 115 V (ac) power supply to the designated terminals.

- Awọn iwọn otutu: Connect up to three low-voltage thermostats to their respective zone terminals (Zone 1, Zone 2, Zone 3).

- Circulators: Connect the circulators for each heating zone to the corresponding pump relay terminals.

- Awọn isopọ igbomikana:

- Connect the boiler end switch (XX) to the boiler's call for heat input.

- If using for domestic hot water priority, connect the DHW end switch.

- For modulating boilers, connect the 0-10 V (dc) or 4-20 mA output to the boiler's modulation input.

- Ilẹ: Ensure all four ground screws are properly connected to the system ground.

After all connections are made, carefully review the wiring for correctness and security before restoring power.

5. Isẹ

Once installed and powered, the Tekmar 303P operates automatically to manage your hydronic heating system. The LED indicators on the front panel provide visual feedback on the system's status.

5.1 LED Atọka

- LED agbara: Ó máa ń tàn ìmọ́lẹ̀ nígbà tí ẹ̀rọ náà bá ń gba agbára.

- RoomResponse™ LED: Indicates when the RoomResponse signal is active.

- LED pataki: Illuminates when Zone 1 is active and operating in priority mode.

- Zone 1, 2, 3 LEDs: Each LED illuminates when its respective zone thermostat is calling for heat and the circulator is active.

5.2 Zone Priority

Zone 1 can be configured for priority operation. When a call for heat comes from Zone 1 (e.g., for domestic hot water), it will override calls from Zone 2 and Zone 3. This ensures that the priority zone receives heat first. Once the priority demand is satisfied, the relay will resume heating for other zones as needed.

5.3 Pump Exercising

The optional pump exercising feature periodically activates the circulators for a short duration, even when there is no call for heat. This prevents the circulator pumps from seizing due to prolonged inactivity, extending their lifespan and ensuring readiness.

5.4 Post Purge

With the optional post purge feature enabled, the circulator for the last operating zone will continue to run for a brief period after the thermostat's call for heat has ended. This helps to extract residual heat from the heating system, improving overall energy efficiency.

6. Itọju

The Tekmar 303P Switching Relay is designed for reliable, long-term operation with minimal maintenance. However, periodic checks can help ensure optimal performance.

- Ayewo wiwo: Annually inspect the unit for any signs of physical damage, loose wiring, or corrosion.

- Ninu: Keep the unit's exterior clean and free of dust. Use a soft, dry cloth. Do not use abrasive cleaners or solvents.

- Ṣayẹwo Fuse: If a zone or the entire unit loses power, check the fuses. The unit includes two spare fuses. Always replace fuses with the correct type and rating (T5A 250 V slow blow).

- Afẹfẹ: Ensure that the ventilation slots on the enclosure are not obstructed to prevent overheating.

CAUTION: Disconnect power to the unit before performing any maintenance or fuse replacement.

7. Laasigbotitusita

This section provides solutions to common issues you might encounter with your Tekmar 303P Switching Relay. For problems not listed here, or if issues persist, contact qualified service personnel.

| Isoro | Owun to le Fa | Ojutu |

|---|---|---|

| No Power LED / Unit is off | No power supply; Blown fuse; Loose wiring. | Check circuit breaker; Replace fuse (T5A 250 V slow blow); Verify all power connections are secure. |

| Zone not heating / Circulator not running | Thermostat not calling for heat; Loose wiring to thermostat or circulator; Blown pump relay fuse; Zone priority active. | Check thermostat setting; Inspect wiring connections; Replace pump relay fuse; Verify if Zone 1 priority is active and satisfied. |

| Igbomikana ko ibọn | Boiler end switch wiring issue; Boiler lockout; No call for heat from any zone. | Check boiler end switch connections; Consult boiler manual for lockout codes; Ensure at least one zone is calling for heat. |

| RoomResponse™ LED not active | Feature not enabled; Wiring issue to modulating boiler; Boiler not compatible. | Refer to installation manual for RoomResponse™ setup; Check wiring to modulating boiler; Confirm boiler compatibility. |

8. Atilẹyin ọja ati imọ Support

8.1 atilẹyin ọja Alaye

For detailed warranty information regarding your Tekmar 303P Switching Relay, please refer to the official warranty statement included with your product packaging or visit the official Tekmar webAaye naa. Awọn ofin atilẹyin ọja maa n bo awọn abawọn ninu awọn ohun elo ati iṣẹ-ṣiṣe fun akoko kan pato lati ọjọ rira naa.

8.2 Imọ Support

If you require technical assistance, have questions about installation, operation, or troubleshooting that are not covered in this manual, please contact Tekmar customer support. You can usually find contact information, including phone numbers and email addresses, on the Tekmar webaaye tabi ninu iwe ti a pese pẹlu ọja rẹ.

When contacting support, please have your product model number (303P) and any relevant purchase information readily available to expedite assistance.