Ọrọ Iṣaaju

This manual provides essential instructions for the safe and effective operation, setup, maintenance, and troubleshooting of your ESAB EMP 210 Multi-Process Welder. Please read this manual thoroughly before using the equipment to ensure proper function and safety.

Nọmba 1: The ESAB EMP 210 Multi-Process Welder shown with its complete set of accessories, including MIG gun, TIG torch, electrode holder, ground clamp, gas regulator, and welding wire spool. This image illustrates the comprehensive package provided for various welding applications.

Awọn iṣọra Aabo

Always prioritize safety when operating welding equipment. Failure to follow safety guidelines can result in serious injury or death. Refer to relevant safety standards and regulations in your region.

- Wear appropriate personal protective equipment (PPE), including welding helmet, gloves, protective clothing, and safety shoes.

- Rí i dájú pé afẹ́fẹ́ tó péye wà níbẹ̀ kí ó má baà jẹ́ kí èéfín ìgbóná ara wọlé.

- Dáàbò bo àwọn tó ń wòran lọ́wọ́ àwọn ìtànṣán àti ìtasánsán.

- Never weld near flammable materials.

- Rii daju pe ilẹ ti o yẹ ti ẹrọ alurinmorin.

- Ge agbara kuro ṣaaju ṣiṣe itọju eyikeyi tabi yi awọn ohun elo pada.

Ṣeto

1. Unpacking ati ayewo

Fi ìṣọ́ra yọ alurinmorin àti gbogbo àwọn ohun èlò míì kúrò nínú àpótí náà. Ṣe àyẹ̀wò bóyá ìbàjẹ́ bá ṣẹlẹ̀. Fi ìròyìn èyíkéyìí tó bá ṣẹlẹ̀ ránṣẹ́ sí olùpèsè rẹ lẹ́sẹ̀kẹsẹ̀.

2. Asopọ agbara

The ESAB EMP 210 operates on both 120V and 230V AC power. The machine automatically detects the input voltage. Ensure the power source is properly rated for the welder's requirements.

- 120V iṣẹ: Use a dedicated 20A circuit.

- 230V iṣẹ: Use a dedicated 30A circuit.

3. Gas Connection (MIG/TIG)

For MIG and TIG welding, connect the appropriate shielding gas cylinder (e.g., Argon, C25) to the regulator provided. Attach the gas hose from the regulator to the gas inlet on the rear of the welder.

4. Welding Lead Connections

So ilẹ clamp to the appropriate terminal on the welder and secure it to the workpiece. Connect the MIG gun, TIG torch, or electrode holder to their respective terminals as required for the chosen welding process.

Nọmba 2: A oke-isalẹ view of the ESAB EMP 210 welder, highlighting its compact design and integrated handle for portability. This perspective shows the overall form factor of the unit, which is designed for easy transport and setup.

Awọn ilana Iṣiṣẹ

The ESAB EMP 210 offers MIG, Stick (MMA), and TIG (Lift TIG) welding capabilities. Select the desired process using the control panel.

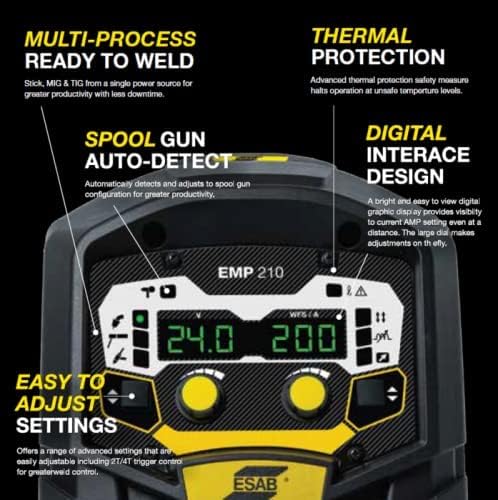

Nọmba 3: Alaye view of the ESAB EMP 210's digital control panel. This image shows the clear display for voltage ati amperage, along with the intuitive adjustment knobs and process selection buttons, emphasizing the "Digital Interface Design" and "Easy to Adjust Settings" features.

1. Iṣakoso igbimo Loriview

The digital interface allows for precise control over welding parameters. Use the large dial and buttons to navigate menus and adjust settings such as amperage, voltage, and wire feed speed.

2. MIG Welding (GMAW)

- Install the appropriate welding wire spool and feed it through the MIG gun.

- Select MIG mode on the control panel.

- Satunṣe voltage and wire feed speed according to the material thickness and wire type.

- Ensure gas flow is set correctly (typically 15-25 CFH for solid wire).

3. Stick Welding (MMA/SMAW)

- Connect the electrode holder and ground clamp.

- Yan Ipo Stick.

- Fi elekitirodu to yẹ sinu ohun ti o dimu naa.

- Ṣatunṣe amperage based on electrode type and diameter.

4. TIG Welding (GTAW - Lift TIG)

- Connect the TIG torch and ground clamp.

- Yan ipo TIG.

- Ensure pure argon shielding gas is connected and flowing.

- Ṣatunṣe amperage for the material and tungsten electrode size.

- Initiate arc using the Lift TIG method.

Nọmba 4: An individual performing welding operations with the ESAB EMP 210 Multi-Process Welder. The welder is visible in the background, and the operator is focused on the workpiece, demonstrating the machine in an active work environment.

Itoju

Regular maintenance ensures the longevity and optimal performance of your ESAB EMP 210 welder.

- Ojoojumọ: Clean the MIG gun nozzle, contact tip, and diffuser. Check ground clamp and cable connections.

- Ọsẹ-oṣooṣu: Inspect all cables for damage. Clean the wire feed mechanism. Check gas hose for leaks.

- Lẹẹkọọkan: Use compressed air to blow dust and debris from inside the machine (ensure power is disconnected). Inspect cooling fan for obstructions.

- Replace worn consumables (contact tips, nozzles, electrodes, tungsten) as needed.

Laasigbotitusita

Refer to the following table for common issues and their potential solutions. If a problem persists, contact ESAB customer support.

| Isoro | Owun to le Fa | Ojutu |

|---|---|---|

| Ko si Arc | No power, poor ground connection, incorrect settings, faulty torch/electrode holder. | Check power supply, ensure solid ground, verify settings, inspect connections. |

| Ko dara Weld Didara | Incorrect settings, contaminated material, improper technique, worn consumables. | Adjust parameters, clean workpiece, review technique, replace consumables. |

| Wire Feeding Issues (MIG) | Incorrect tension, clogged liner, wrong contact tip, tangled wire. | Adjust drive roll tension, clean/replace liner, use correct contact tip, untangle wire. |

| Overheating (Thermal Protection) | Exceeding duty cycle, poor ventilation. | Allow machine to cool, ensure adequate airflow around the unit. |

Awọn pato

| Ẹya ara ẹrọ | Ẹ̀kúnrẹ́rẹ́ |

|---|---|

| Brand | ESAB |

| Nọmba awoṣe | 0324-0075 (EMP 210) |

| Iṣagbewọle Voltage | 120V / 230V DC (Auto-sensing) |

| Awọn ilana alurinmorin | MIG (GMAW), Stick (MMA/SMAW), TIG (GTAW - Lift TIG) |

| Max o wu Lọwọlọwọ | 200A |

| Iwọn Nkan | 43 iwon |

| Ọja Mefa | 23 x 18.5 x 18 inches |

| Ọjọ Akọkọ Wa | Oṣu Kẹwa Ọjọ 28, Ọdun 2021 |

Atilẹyin ọja ati Support

Alaye atilẹyin ọja

For detailed warranty terms and conditions, please refer to the official ESAB warranty statement included with your product or visit the official ESAB website. Warranty coverage typically includes defects in materials and workmanship for a specified period from the date of purchase.

Onibara Support

If you encounter any issues or have questions regarding your ESAB EMP 210 welder, please contact ESAB customer support. You can find contact information on the official ESAB webojula tabi nipasẹ rẹ ni aṣẹ onisowo.

Òṣìṣẹ́ ESAB Webojula: www.esab.com