1. Ifihan

This instruction manual provides essential information for the safe and effective operation, setup, and maintenance of your CREWORKS Mini Metal Lathe, Model CT-2260A. This machine is designed for precision metalworking tasks, including turning, drilling, threading, and cutting various materials such as wood, plastics, brass, and aluminum. Please read this manual thoroughly before operating the lathe to ensure proper usage and to prevent injury or damage to the equipment.

2. Awọn ilana aabo

Operating any machinery carries inherent risks. Adhering to these safety guidelines is crucial for your protection and the longevity of the equipment.

- Ka iwe afọwọkọ naa: Always read and understand the entire instruction manual before operating the lathe.

- Ohun elo Idaabobo Ti ara ẹni (PPE): Always wear safety glasses or a face shield. Hearing protection is recommended. Avoid loose clothing, jewelry, and long hair that could get caught in moving parts.

- Agbegbe Iṣẹ: Keep your work area clean, well-lit, and free from clutter. Ensure adequate space around the lathe for safe operation.

- Asopọ agbara: Ensure the lathe is properly grounded. Disconnect power before performing any maintenance, adjustments, or when changing accessories.

- Iṣẹ iṣẹ to ni aabo: Nigbagbogbo rii daju awọn workpiece ni labeabo clamped ni Chuck tabi kollet ṣaaju ki o to bẹrẹ ẹrọ naa.

- Tool Security: Ensure all cutting tools are properly sharpened and securely mounted in the tool post.

- Iduro Pajawiri: Mọ ararẹ pẹlu ipo ati iṣẹ ti bọtini idaduro pajawiri.

- Abojuto: Maṣe fi ẹrọ ti n ṣiṣẹ laibikita.

- Awọn ọmọde ati Awọn Oluduro: Pa awọn ọmọde ati awọn eniyan laigba aṣẹ kuro ni agbegbe iṣẹ.

- Machine Condition: Do not operate the lathe if it is damaged or malfunctioning. Report any issues immediately.

3. Ọja Ipariview

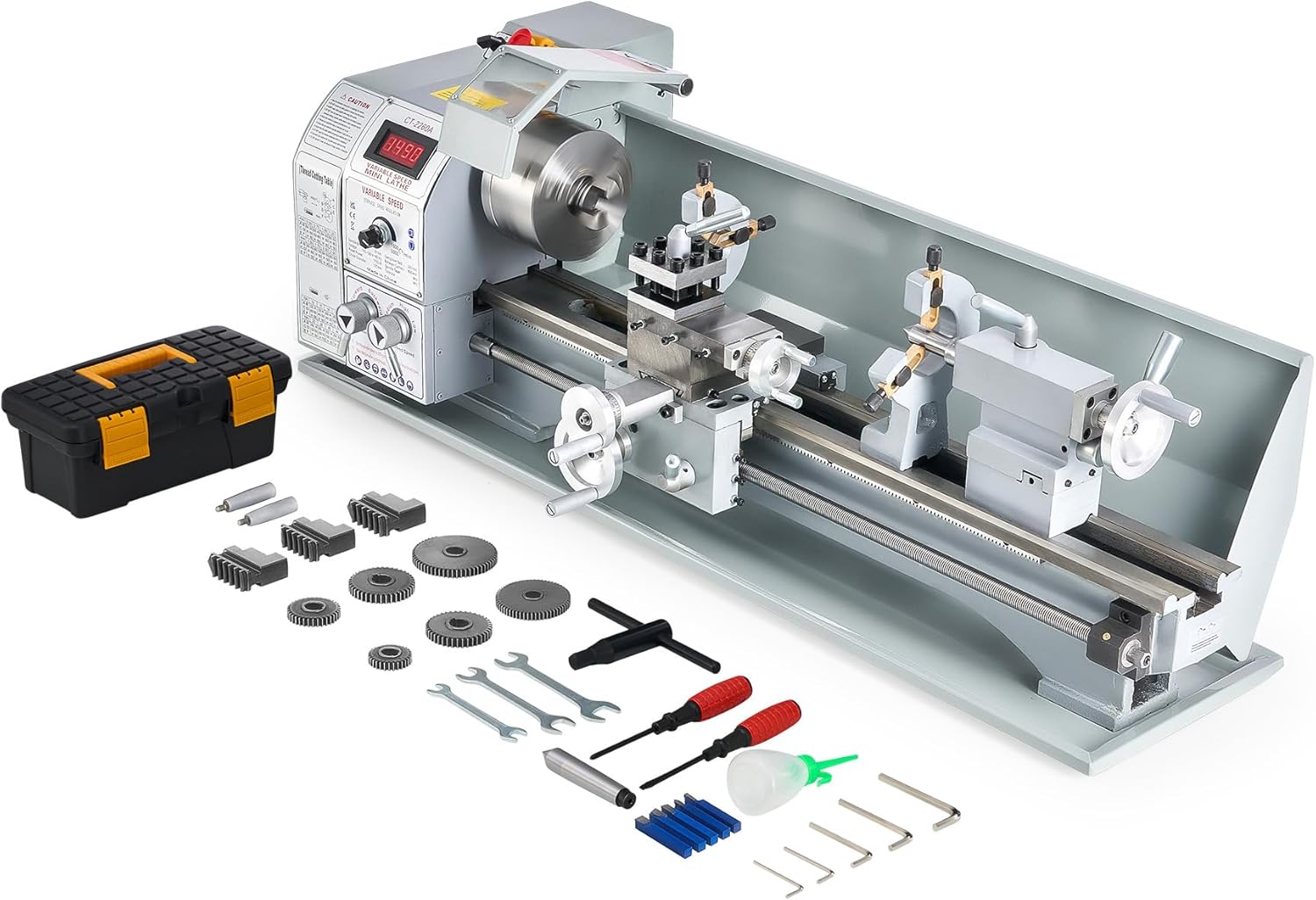

The CREWORKS Mini Metal Lathe (Model CT-2260A) is a robust benchtop machine constructed from cast iron, stainless steel, and ABS components. It features an 1100W brushless motor, a high-precision 3-jaw chuck, and a digital display for real-time speed monitoring. With an 8.7-inch swing over bed and a 23.6-inch distance between centers, it accommodates small to medium-sized projects. The 1.5-inch spindle bore and 4-way tool post provide versatility for various machining operations.

The CREWORKS Mini Metal Lathe (Model CT-2260A) with included accessories, designed for precision metalworking tasks.

Alaye view highlighting the digital speed display, carriage handwheel, cross slide handwheel, compound control wheel, and tail feed handwheel for precise control.

Illustrates various applications of the 9" x 24" mini metal lathe, including metalworking, drilling, internal and external threading, polishing, gyroscope processing, woodworking, screw turning, and slot turning.

4. Eto

Proper setup is essential for safe and accurate operation.

4.1 Unpacking ati ayewo

- Fi iṣọra yọ lathe ati gbogbo awọn ẹya ẹrọ kuro ninu apoti.

- Inspect all components for any signs of shipping damage. If damage is found, contact customer service immediately.

- Verify that all listed accessories are present.

4.2 Iṣagbesori Lathe

- Mount the lathe securely to a sturdy workbench or stand capable of supporting its weight (approximately 165.3 lbs / 75 kg).

- Ensure the mounting surface is level to maintain machining accuracy.

- Use appropriate fasteners to prevent any movement during operation.

4.3 Asopọ agbara

- Connect the lathe to a suitable AC power outlet. Ensure the power supply matches the machine's requirements (1100W).

- Nigbagbogbo lo iṣan ti o wa lori ilẹ.

4.4 Ni ibẹrẹ Cleaning ati Lubrication

- Clean any protective grease or oil from the machine's surfaces, especially the bedways, lead screws, and chuck, using a suitable degreaser.

- Apply a thin layer of machine oil to all moving parts and unpainted surfaces to prevent rust and ensure smooth operation.

5. Awọn ilana Iṣiṣẹ

This section details the basic steps for operating your mini metal lathe.

5.1 Agbara Titan / Pa ati Iṣatunṣe Iyara

- Yi agbara akọkọ pada si ipo 'ON'.

- Use the variable speed control knob to adjust the spindle speed. The digital display will show the current RPM (0 to 3000 rpm).

- Always start at a lower speed and gradually increase as needed for the material and operation.

Close-up of the digital display for variable speed adjustment, showing the current spindle speed up to 3000 rpm.

5.2 Chuck isẹ

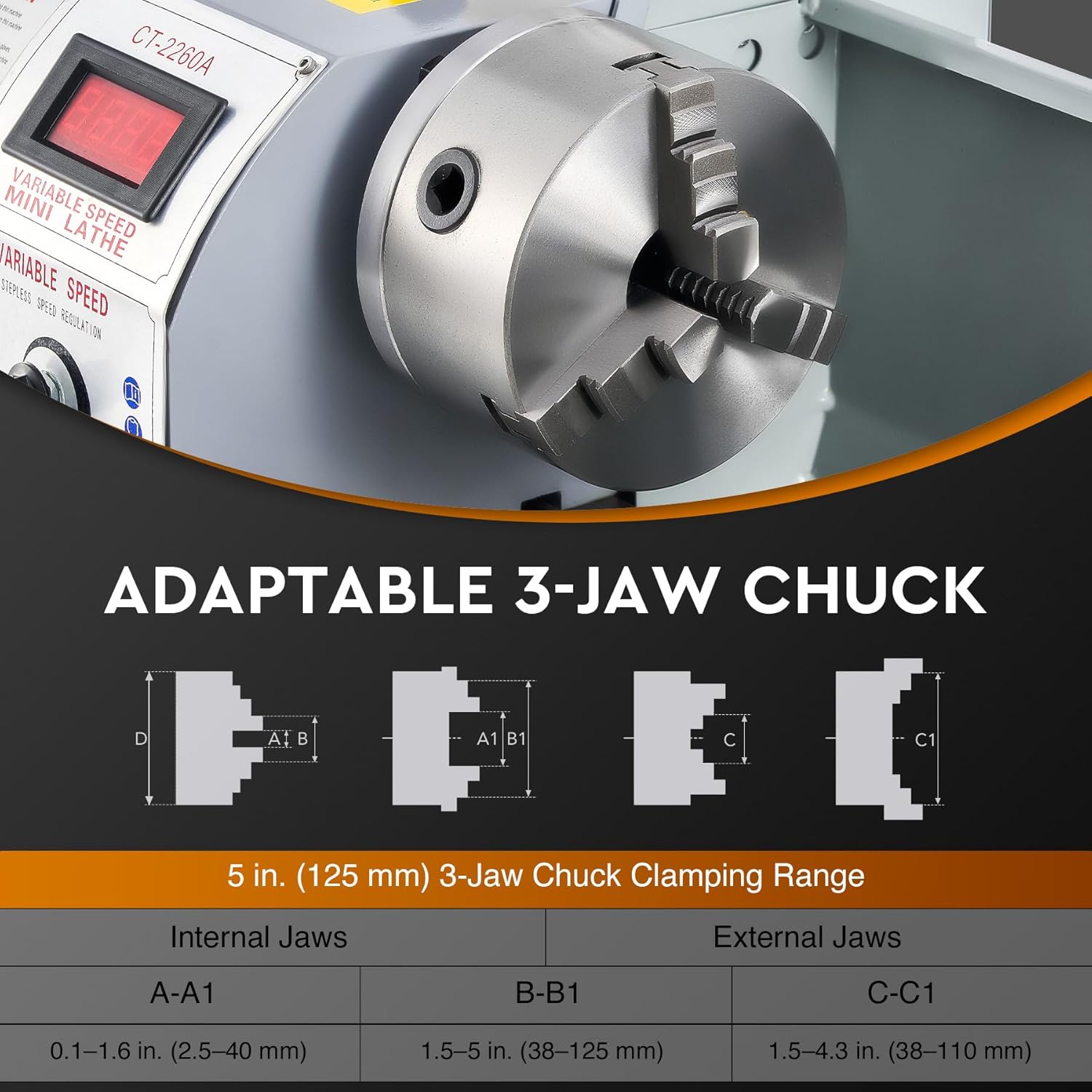

- The lathe is equipped with a 5-inch (125 mm) 3-jaw chuck.

- To open or close the jaws, insert the chuck key into the chuck and rotate.

- Ensure the workpiece is centered and securely clamped before starting the lathe. Remove the chuck key before turning on the machine.

Diagram illustrating the adaptable 5-inch (125 mm) 3-jaw chuck and its clamping range for internal and external jaws.

5.3 Tool Post and Tooling

- Mount cutting tools securely in the 4-way tool post.

- Adjust the tool height so that the cutting edge is precisely on the centerline of the workpiece for optimal results.

5.4 Basic Machining Operations

- Yipada: Use the carriage handwheel and cross slide handwheel to feed the cutting tool along and across the workpiece.

- Liluho: Mount a drill chuck in the tailstock and advance the drill into the workpiece using the tail feed handwheel.

- Titẹ: Refer to the threading chart on the machine for appropriate gear settings and feed rates for internal and external threads.

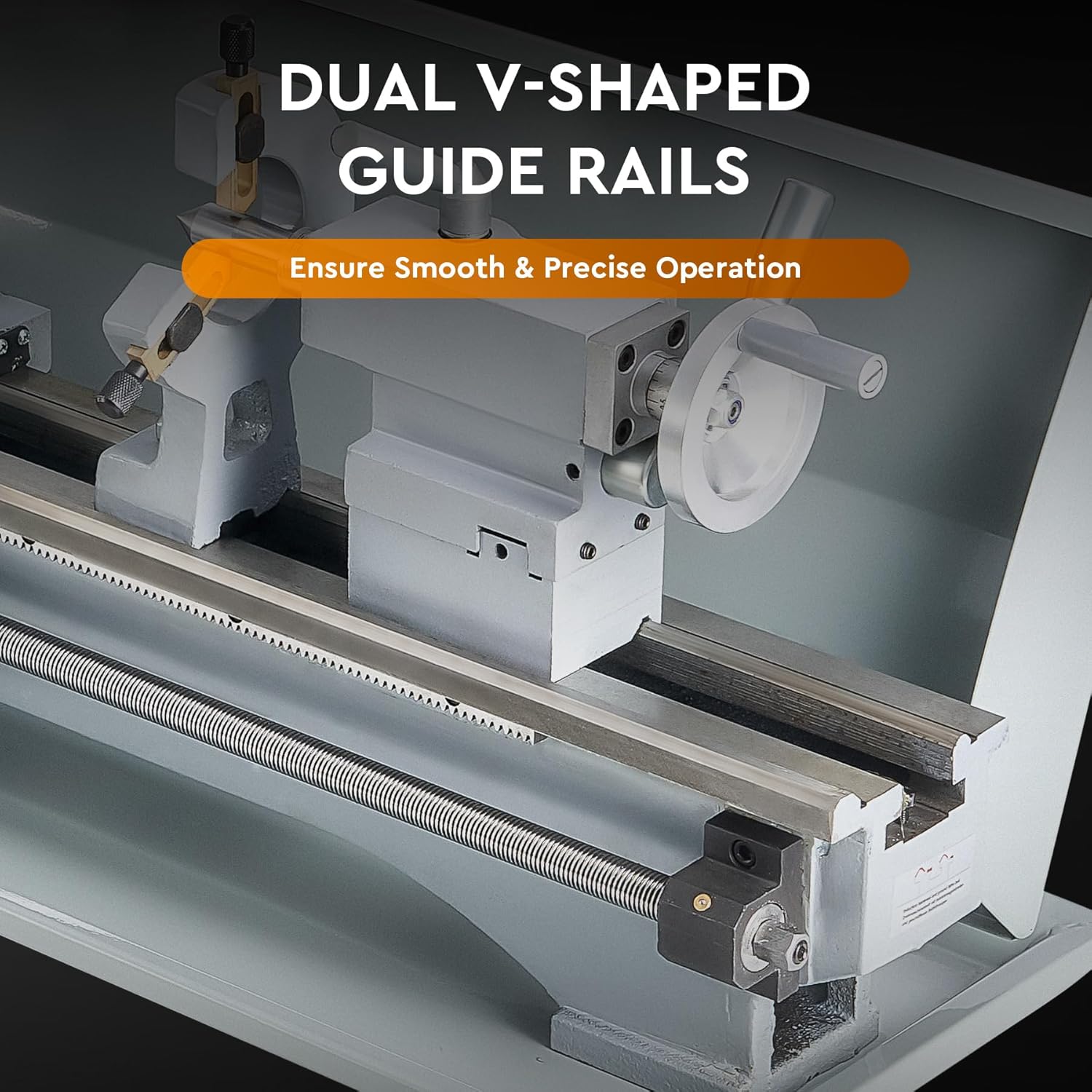

View of the dual V-shaped guide rails, which ensure smooth and precise operation of the carriage and other components.

Ti abẹnu view of the durable metal gear set, designed for wear resistance and efficient power transmission.

6. Itọju

Regular maintenance ensures the longevity and performance of your lathe.

- Ninu: After each use, clean all chips, dust, and debris from the machine, especially from the bedways, lead screws, and chuck. Use a brush or air gun (with caution and eye protection).

- Lubrication: Periodically lubricate all moving parts, including the bedways, lead screws, gears, and bearings, according to the lubrication points indicated in the machine's diagrams (if available). Use appropriate machine oil.

- Ayewo: Regularly inspect for wear, damage, or loose fasteners. Tighten any loose bolts or screws. Check the condition of the drive belt and replace if worn.

- Itọju Chuck: Keep the chuck jaws clean and lubricated. Periodically remove the chuck for thorough cleaning and inspection.

- Awọn ohun elo itanna: Rii daju pe gbogbo awọn asopọ itanna wa ni aabo ati ofe lọwọ ibajẹ.

7. Laasigbotitusita

Abala yii n ṣalaye awọn ọran ti o wọpọ ti o le ba pade ati awọn solusan agbara wọn.

- Ẹrọ Ko Ibẹrẹ:

- Ṣayẹwo boya okun agbara ti wa ni edidi ni aabo.

- Rii daju pe iyipada agbara wa ni ipo 'ON'.

- Check the circuit breaker or fuse for the power outlet.

- Ensure the emergency stop button is not engaged.

- Gbigbọn Pupọ tabi Ariwo:

- Ensure the lathe is securely mounted to the workbench.

- Check if the workpiece is properly secured in the chuck and balanced.

- Inspect cutting tools for sharpness and proper mounting.

- Check for loose components or worn bearings.

- Poor Surface Finish on Workpiece:

- Ensure cutting tools are sharp and correctly ground.

- Adjust cutting speed and feed rate for the material being machined.

- Check for excessive tool overhang or chatter.

- Verify the machine is stable and free from vibration.

- Awọn gige ti ko pe:

- Ensure the workpiece is properly centered and clamped.

- Check for backlash in the lead screws and adjust if necessary.

- Verify that the tool height is set correctly to the centerline.

For issues not covered here, or if troubleshooting steps do not resolve the problem, please contact CREWORKS customer support.

8. Awọn pato

Detailed technical specifications for the CREWORKS Mini Metal Lathe (Model CT-2260A).

Technical specifications and dimensions of the CREWORKS Mini Metal Lathe, including material, power, swing over bed, spindle bore, tailstock taper, spindle taper, thread ranges, center distance, chuck diameter, max spindle speed, and net weight.

| Sipesifikesonu | Iye |

|---|---|

| Olupese | Awọn iṣẹ ṣiṣe |

| Nọmba apakan | CT-2260A |

| Iwọn Nkan | 165.3 poun (75 kg) |

| Ọja Mefa | 44.88 x 18.9 x 19.29 inches |

| Ara | 9"×24" |

| Ohun elo | Cast Iron, Stainless Steel, ABS |

| Orisun agbara | AC |

| Wattage | 1100 watt |

| Golifu Lori Bed | 8.7 inch (220 mm) |

| Ijinna Laarin Awọn ile-iṣẹ | 23.6 inch (600 mm) |

| Spindle Bore | 1.5 inch (38 mm) |

| Chuck Diamita | 5 inch (125 mm) |

| Max. Spindle Speed | 3000 rpm |

| Tailstock Taper | MT#2 |

| Spindle Taper | MT#5 |

| Metric Thread Range | 0.3-3 mm |

| Inch Thread Range | 8–44 tpi |

| Ti beere awọn batiri? | Rara |

9. Atilẹyin ọja ati Support

For warranty information, please refer to the terms and conditions provided at the time of purchase or contact CREWORKS directly. CREWORKS is committed to providing quality products and customer satisfaction.

If you require technical assistance, have questions about operation, or need to report an issue, please contact CREWORKS customer service. Have your model number (CT-2260A) and purchase details ready for efficient support.